Media design processes

First year second semester architecture students (TU Braunschweig, Institute of Media Design) are exposed to rule surface based geometries and their developable properties. Generative design and fabrication concepts are introduced via a series of analog and digital exercises.

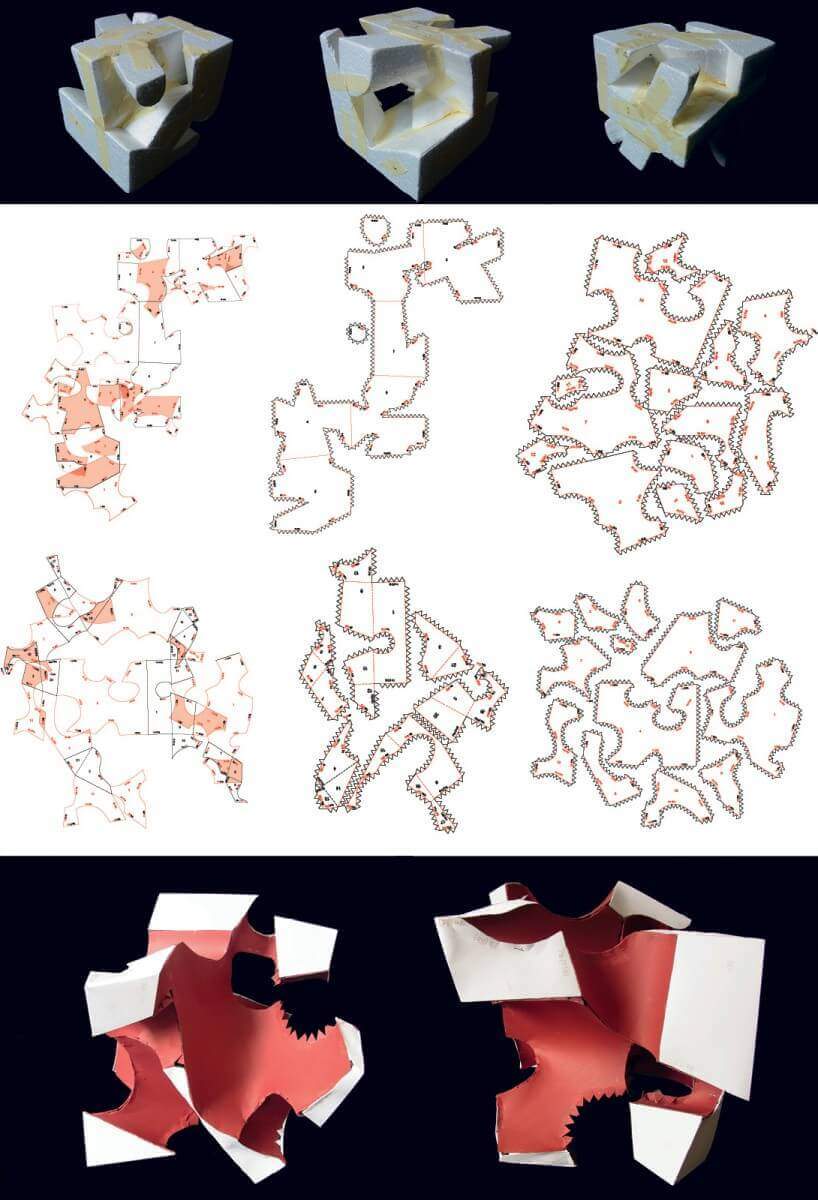

A 10cm3 polystyrene block is shaped using rigid hot wire cutters to approximate ruled surface geometries.

The resulting surfaces are traced using Mylar and digitally scanned for post-processing using vector based CAD software.

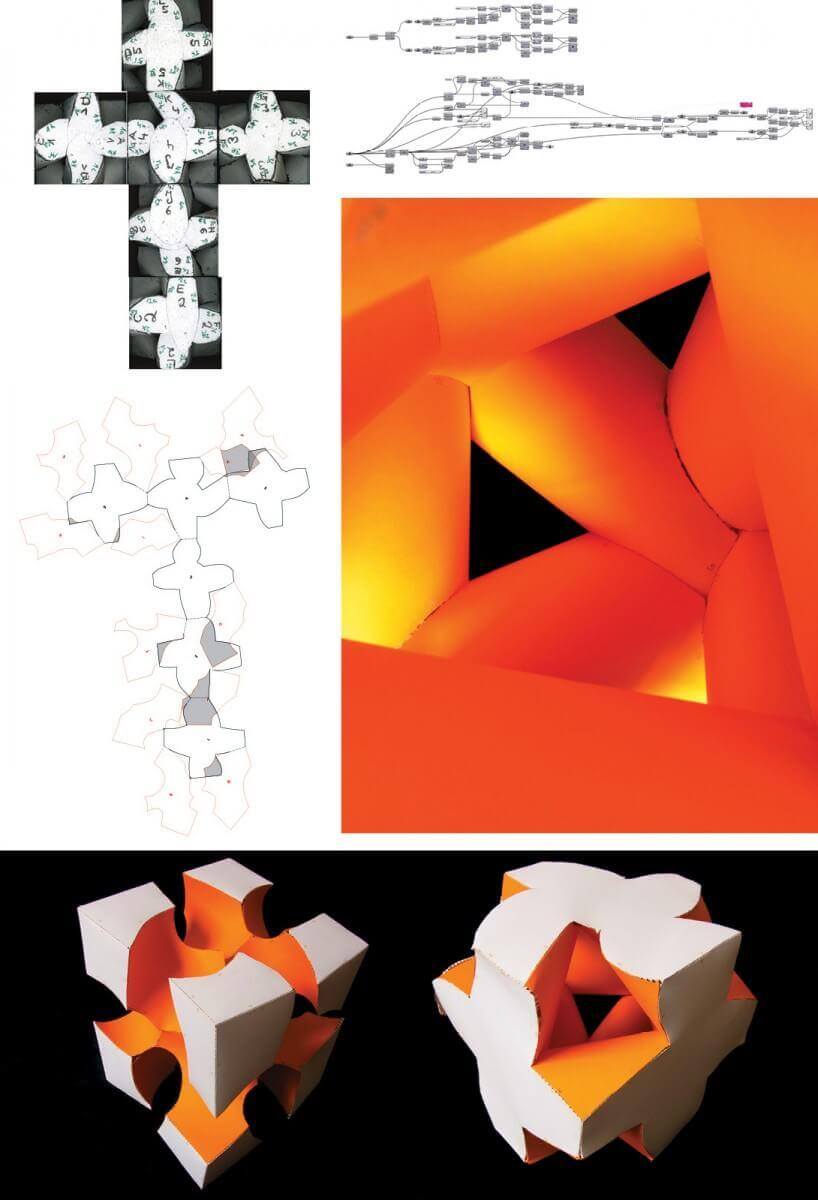

The task is to scale the scanned parts by 300% and generate two dimensional drawings communicating the assembly to rebuild the shapes out of flat paper stock; nesting patterns, labels and cutting paths are manually created in the digital environment to prepare the data for laser cutting.

Parallel to this pseudo numeric process the students are introduced to iterative design tools. Their proto-shapes are remodeled in the virtual 3D environment, unfolded using interactive scripts; labels, notches, nesting patterns and cutting paths are automated.

These procedures address notions of: transformation, translation/scaling, materiality, iteration and digital-crafting.

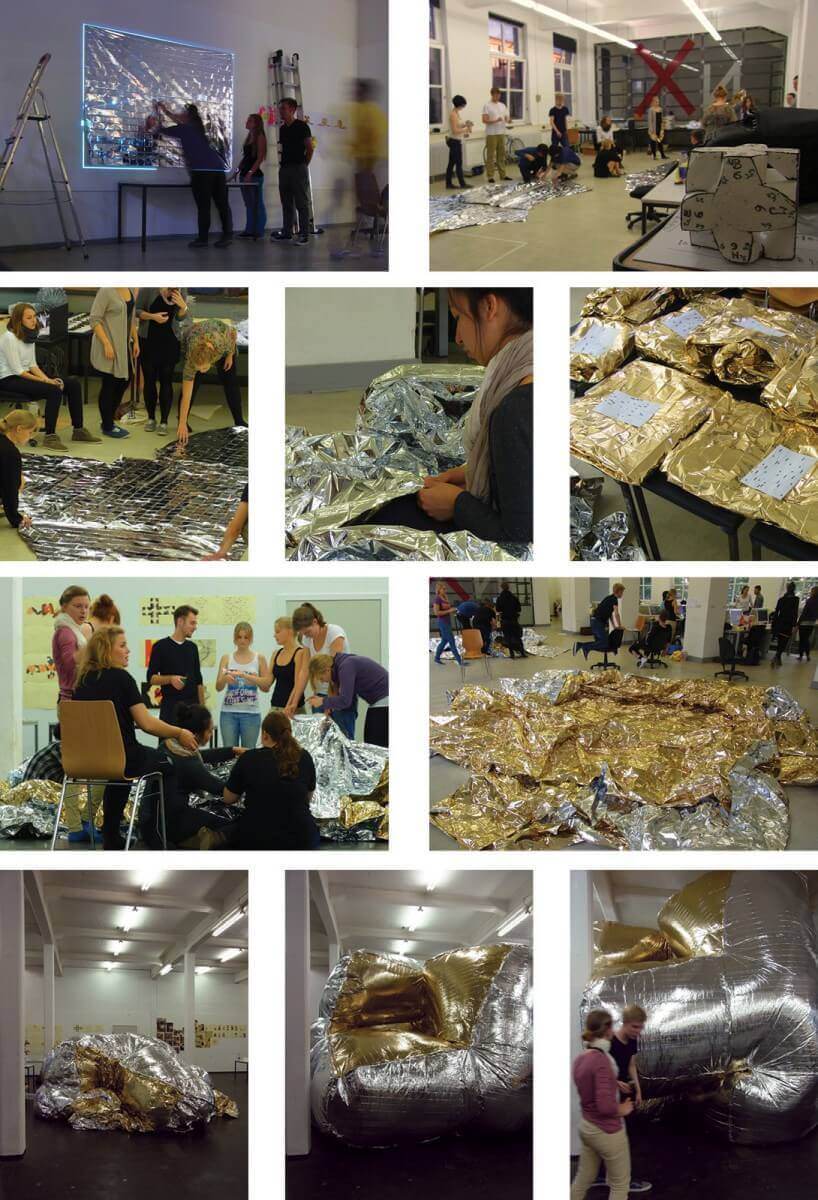

The final step, “Blowup” – scales a selected prototype by a much as 60 times. The digital scripts generate the parts for tracing onto Mylar foil using a beamer. The fabrication process requires a coordinated team effort to produce the piece in two days. The shape is assembled in three stages and “welded” using clear adhesive tape. The Mylar foil is extremely fragile and requires utmost handling care. The final envelop is inflated in approximately 30 minutes using two small blowers and occupies a volume of approximately 6m3.